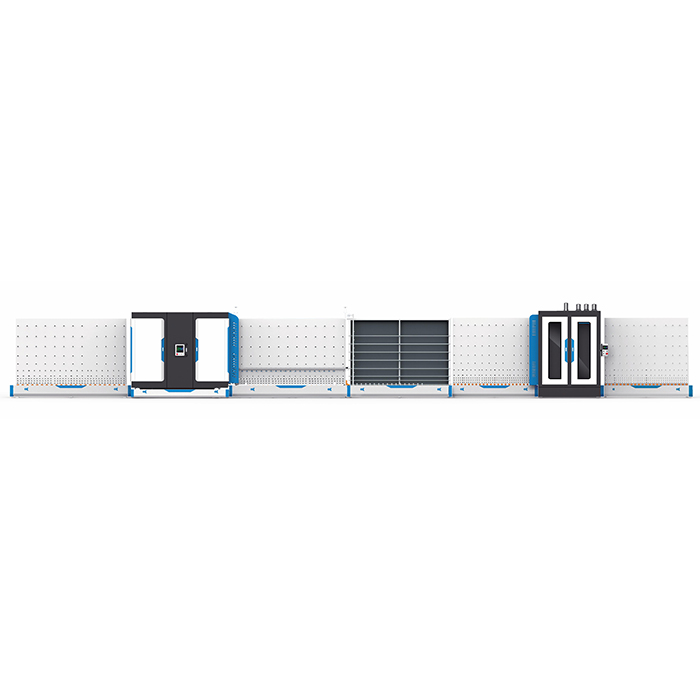

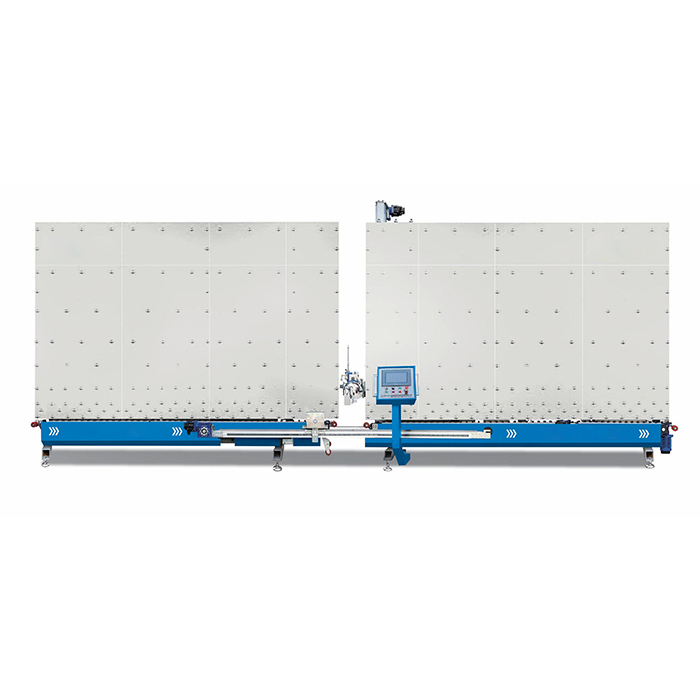

Butyl Sealant Extruder Machine

◎ Suitable for the first seal of insulating glass aluminum spacer.

◎ The whole structure is modular, with low failure rate and easy maintenance.

◎ In order to keep the stable glue output performance, advanced gas-liquid pressurization technology is adopted.

◎ Touch screen temperature control, high precision, simple operation.

◎ Transmission speed 5-speed control function.

◎ Real-time instrument display of glue quantity, early warning.

◎ The width of the rubber nozzle can be automatically adjusted by induction, which can quickly locate.

◎ The amount of butyl rubber is 14KG, and the width of processed aluminum strip is 4-30mm.

◎ Automatic refueling of fuel tank is clean and labor-saving.

TECHNICAL PARAMETER | DJT02 | DJT03 |

Power supply | 220V/50Hz | 220V/50Hz |

Total power | 4.0kW | 2.6kW |

Conveying speed | 18~40m/min | 21m/min/28m/min |

Extruding temperature | 110~160℃ | 110~160℃ |

Air pressure | 0.5~0.8MPa | 0.5~0.8MPa |

Extruding pressure | 12~18MPa | 12~18MPa |

Adjustable range of extruding nozzle | 6~27mm | 6~27mm |

Width of machined aluminum strip | 4~30mm | 4~30mm |

Rubber bucket capacity | 14kg | 14kg |

Overall dimension | 3000×700×900mm | 3000×700×900mm |

INQUIRY

CATEGORIES

CONTACT US

Contact: Marc Wang

Phone: 0086-15554250908

E-mail: info@phc-glassmachine.com

Whatsapp:0086-15554250908

Add: Qingdao, Shandong,China